Industry 4.O - Optimizing Productivity

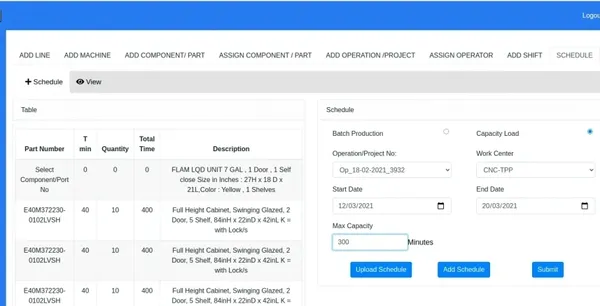

Many manufacturers find it hard to identify those specific losses that contribute to low machine productivity as they are difficult to identify, record and analyze. So, manufacturers are looking to digitize day-to-day manufacturing processes & support in making the move toward smart factory transformation.

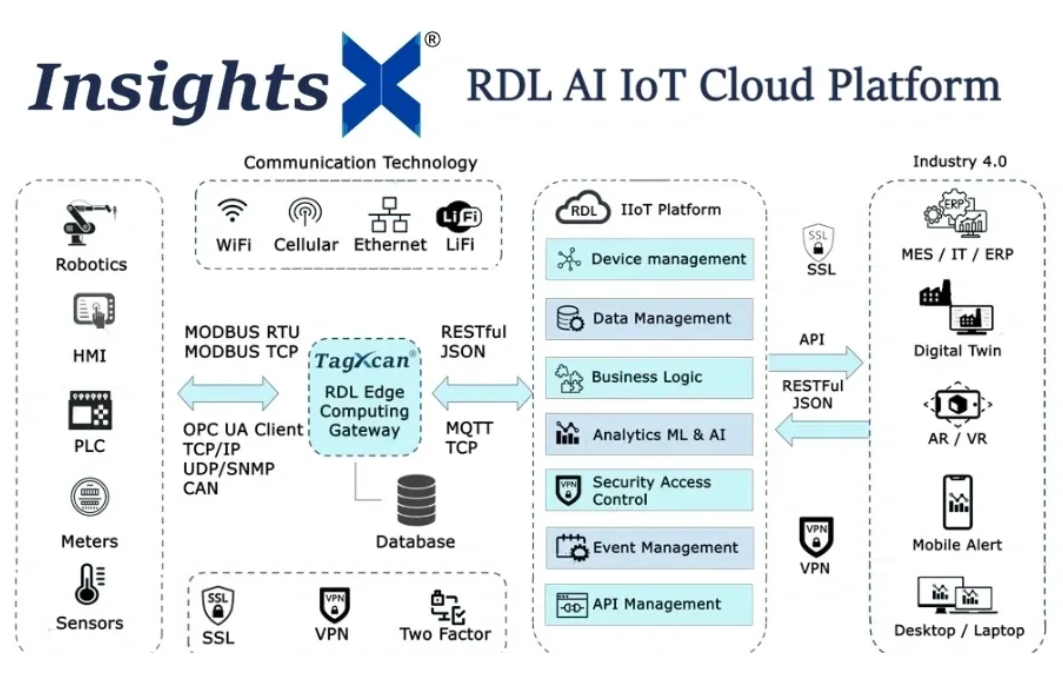

Our Shop Floor AI solution is designed to optimize manufacturing operations by leveraging artificial intelligence technology. The solution helps businesses improve productivity, reduce costs and enhance quality control by providing real-time insights and predictive analytics.

Digitally Transform your Shop Floor

- Unlock Hidden Production Capacity.

- Minimize Unplanned Down time.

- Shorten Production Lead Time.

- Reduce Product Defect.

- Increase Machine Availability.